Thermosiphon channel instead of heat pipe

Article by Ralph Schmidt in "Elektronik" (issue 19.2025)

The integration of a closed thermosiphon channel in aluminium heat sinks enables significantly more efficient heat distribution than with conventional heat pipes or purely conductive aluminium profiles. This is demonstrated by the example of CooliBlade's NEOcore technology. Simulations and measurement data show lower component temperatures and more even utilisation of the cooling structure.

Advancing miniaturisation and increasing performance requirements are increasing power loss density in power electronic systems. The resulting hotspots place high demands on thermal management. CooliBlade's NEOcore technology was developed to meet this challenge with an air-based solution based on a thermosiphon channel integrated into aluminium.

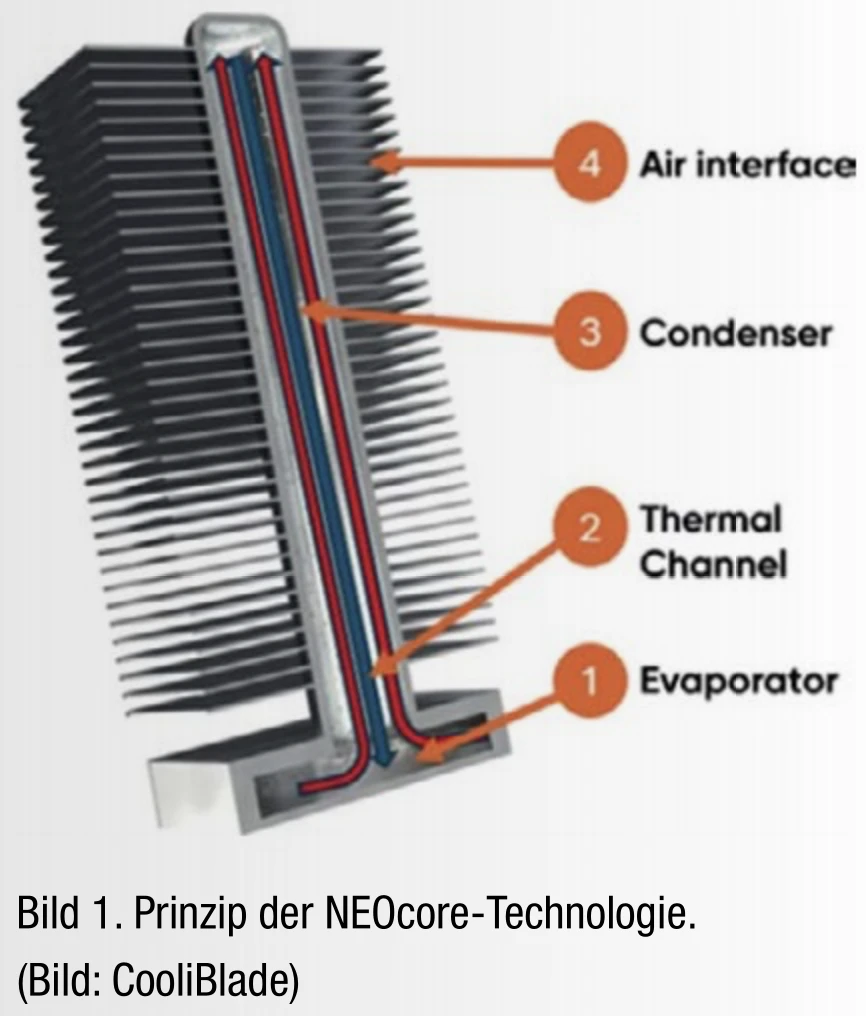

The central element of the technology developed by Finnish start-up CooliBlade is a thermally active channel that is integrated directly into the aluminium structure of the heat sink. This channel utilises a phase change process and achieves an effective thermal conductivity of 200,000 W/mK – about 1,000 times the thermal conductivity of aluminium. This allows up to 3 kW of power dissipation per module to be dissipated, even in compact installation spaces. The heat sinks are designed so that a large-area evaporator maximises heat absorption, while the directly integrated channel reduces thermal resistance. The downstream condensation area allows the working medium to be reconverted into liquid before the dissipated heat is released into the environment at an optimised air transition.

Comparison with conventional solutions

In classic heat pipe designs, separate heat pipes are inserted into milled channels and either glued or soldered in place. This creates additional contact resistance between the heat pipe, adhesive and aluminium. In contrast, the NEOcore channel is an integral part of the heat sink, eliminating these interfaces. This reduces the overall resistance and simplifies production at the same time.

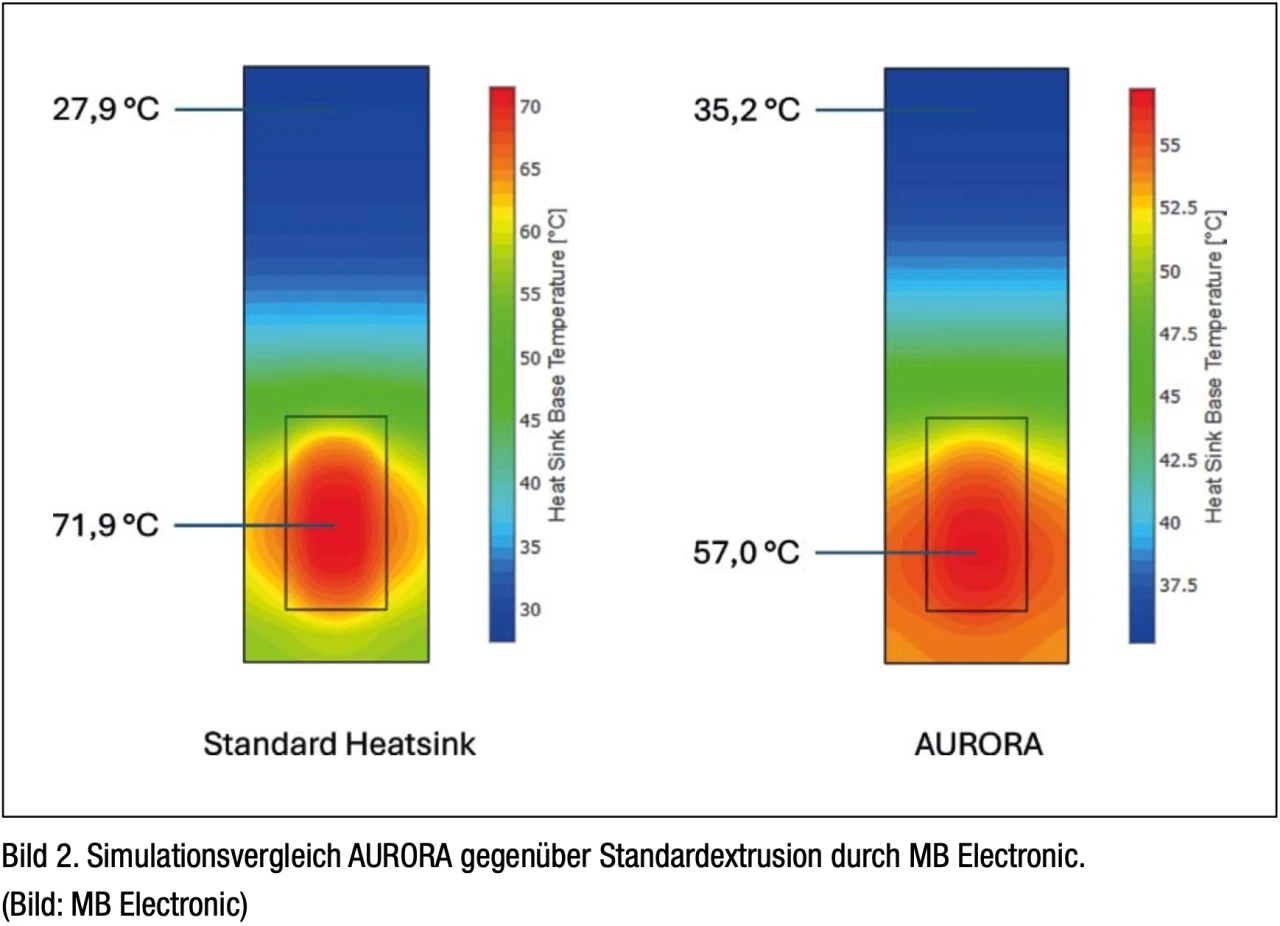

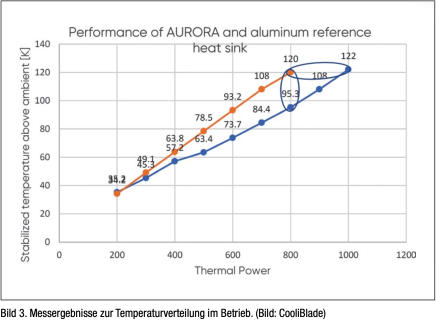

Simulation and measurement results: NEOcore versus standard finned heat sink

For a comparative study, a standard finned heat sink and a NEOcore heat sink (Aurora model) with identical dimensions were analysed using a Semix 3P IGBT module. The simulation showed that with the conventional solution, cooling is limited to the area immediately above the module, while the majority of the heat sink remains thermally inactive. In contrast, the NEOcore channel distributes the heat evenly across the entire fin structure, thereby activating the entire cooling surface for convection. These results were confirmed by measurements. The NEOcore heat sink remained significantly cooler across the entire load range. The advantage increased with increasing power dissipation. A dry-out effect, as can occur with heat pipes under high thermal load, was not observed.

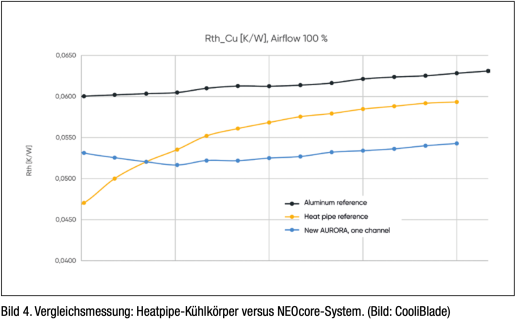

Temperature advantages even over heat pipe solutions

In a further comparison with a heat sink that uses embedded heat pipes, the NEOcore solution consistently delivered better temperature values. Across the entire operating range, the heat sink temperature remained around 15% lower on average. From a load of around 25% of the rated power, the heat pipe variant increasingly lost efficiency, while the NEOcore technology remained consistently powerful.

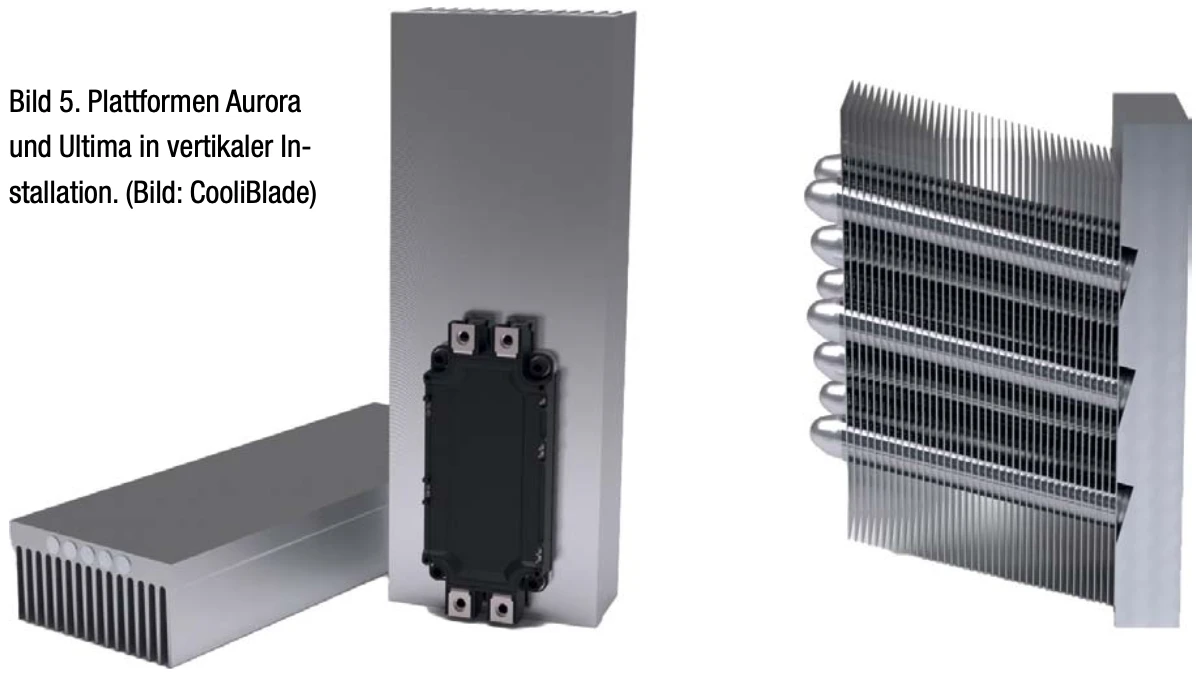

Thermal characteristics of the platforms

CooliBlade offers two platforms for different application requirements. The Aurora series is based on an extruded aluminium profile with an integrated NEOcore channel and is suitable for single modules. With dimensions of 350 mm × 72 mm × 61 mm, the heat sink achieves a thermal resistance of 67.9 K/kW at 1 kW power dissipation and an air flow of 300 m³/h. The recommended installation position is vertical. The Ultima series extends this concept with additional heat transfer channels in the fins. This improves surface activation and further reduces thermal resistance. The heat sink measures 140 mm × 207 mm × 200 mm and is designed for up to two power modules. At 3 kW power dissipation and 400 m³/h air flow, the thermal resistance is 23.21 K/kW.